Whether shaft misalignment, rotor dynamics, or thermal stability, spindle solutions from Levicron require component developments at many points, which can be purchased from other spindle manufacturers. Such sub-developments can, in turn, be further developed into products with unique properties and made available to the market. This also applies to verifying spindle quality and performance, for which Levicron has designed testing and measuring methods unique in resolution, handling, and sampling rates.

About “ShakesBear”

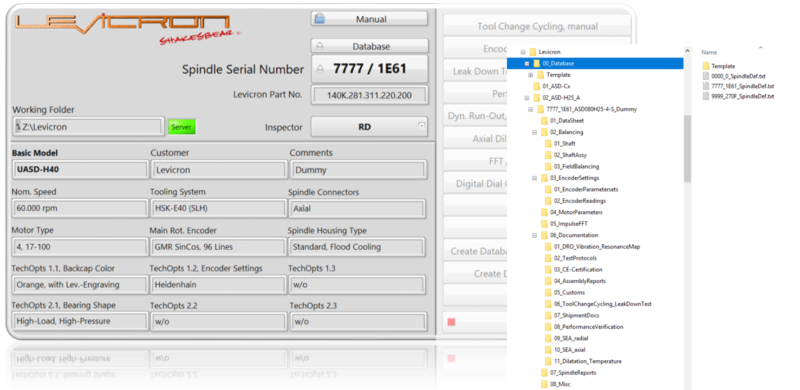

With our spindle test and inspection systems “ShakesBear, Hamlet” and “ShakesBear, Othello,” Levicron provides the end customer or the machine manufacturer with complete test systems for measuring dynamic runout, resonance maps, and the rotational fidelity of spindle systems. All measurements are stored as a protocol and raw data in a higher-level spindle database that can be retrieved at any time. The ShakesBear software combines all measurement, recording, and management modules and allows centralized and self-explanatory working and management.

By refining hardware and software, our ShakesBear systems, Othello and Hamlet V3, enable customized dynamic spindle tests with nanometer resolution at speeds up to 100,000 rpm.

Demo Software available

Do you want to get an idea first? For this purpose, we have generated a ShakesBear demo. You will get actual functionality with the hardware, but you can familiarize yourself with the structure, operation, and database functionality.

Spindle error analysis (error motion) according to ISO230-7 for ultra-precision spindles is complicated. For example, the object being measured against is never perfectly round and deforms quickly due to centrifugal force. A resolution below 1 nm at speeds up to 100,000 rpm requires not only sophisticated hardware but also sophisticated and fast software.

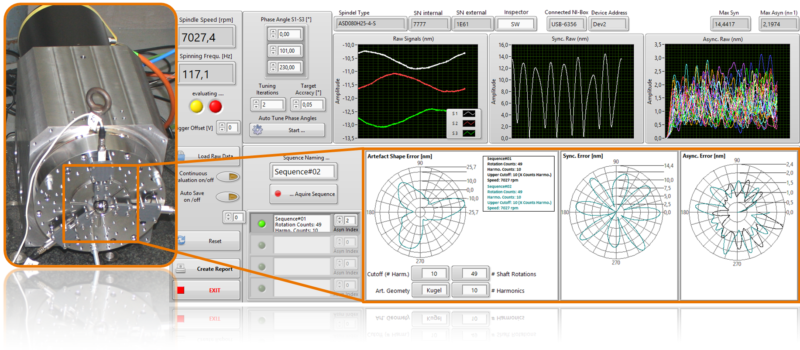

While we have fully automated SEA (Spindle Error Analysis) for our spindle products in our production, we have also developed the entire system into our new ShakesBear V3. With our multi-sensor setup, this dynamic shape error is automatically and continuously separated from the spindle synchronization errors. Likewise, the angles between the sensors must be accurately known. With an integrated algorithm, our ShakesBear software calculates exactly these angles, making the sensor setup much more effortless. Our software contains all the essential test tools we have developed for our internal use and has two dynamic database units, one for the products and one for the system itself.

ShakesBear, Hamlet

The Spindle Error Analysis complete system “ShakesBear Hamlet” was explicitly developed to determine a rotating system’s rotational fidelity (error motion), which detects a direct error separation between the spindle synchronous and artifact molding errors with nanometer resolutions for spindle speeds up to 100,000 rpm. With four high-resolution and fast scanning distance sensors, the radial and axial rotational fidelity with automatic error separation of spindle synchronous and artifact molding errors is determined in one measurement, recorded, and stored as report and raw data. Unified in mobile housing, this allows the connection of a Pc and the sensor technology, with all amplifier and driver units integrated into the housing.

We are happy to offer you customized connection adapters for the spindle system to be examined.

With our ShakesBear Suite, version 3, we have combined all the essential test methods we have developed since Levicron was founded. Qualifying our spindle solutions to the values we specify requires several test modules. These include:

- The dynamic tool runout, spindle vibration, and resonance speed maps.

- Axial shaft growth and temperature with time and spindle speed

- The FFT (Fast Fourier Transformation) analysis and impulse response

- The digital drag pointer dial indicator

- Spindle error analysis (SEA, Error-Motion), DIN-ISO230-7

With these test methods, the user can, on the one hand, qualify his or other spindle products and, on the other hand, cover dynamic machine analyses with the spindle as an exciting force. All measurement and product characteristics are part of a system and product database (ShakesBear, Othello), fully customizable by the user or us. With acceleration recordings, a laser tachometer, capacitive probes with nanometer resolution, and a high-speed A/D conversion, the hardware is designed to work with the software optionally. Even at the nanometer level, at speeds up to 100,000 rpm.

ShakesBear, Othello

The “ShakesBear, Othello” complete spindle inspection system targets the acquisition of dynamic quantities such as tool runout, thermal dilation, and spindle and system resonance maps. It was developed for machine manufacturers who want to test spindle properties in their test bay or for mobile use by end customers. With optionally available integrated operating and computing units, the test system enables mobile and flexible use (with Raspberry Pi and touchscreen). Here, all amplifiers, filters, and driver units are also integrated into one housing to connect the sensors directly. In addition to the spindle characteristics, this analysis system also integrates tests on the overall strategy, which provide information about the machine’s natural frequencies with the spindle as the exciter.

We are happy to offer you customized connection options for the machine spindle to be examined.

| ShakesBear, Hamlet | ShakesBear, Othello | ||

| General | Power Supply | 240 VAC | 240 VAC |

| Internal PC, Touchscreen | n.a. | option | |

| USB 2.0 (or higher) Connector | yes | yes | |

| A/D Converter | Digital Resolution | 16 bit | 16 bit |

| Number of Channels | 8 | 8 | |

| Evaluation | differential | differential | |

| Sampling Rate per Channel | 1,25 MS/s | 250 kS/s | |

| Analog Signal | +/- 10 V | +/- 10 V | |

| Distance Sensing | Physical Principal | capacitive | capacitive |

| Working Distance | 50 µm | 50 µm | |

| Resolution | 1,7 nm | 1,7 nm | |

| Sampling Rate | 100 kHz | 100 kHz | |

| Number of Sensors | 4 | 1 | |

| Vibration Sensing | Physical Principle | Piezo-Mass | Piezo-Mass |

| Cutoff Frequency | 18 kHz | 18 kHz | |

| Sensitivity | 1 V/g | 1 V/g | |

| Number of Sensors | 0 | 1 (Option: 2) | |

| Software Modules | Spindle / Machine Data Base | X | X |

| Server Connection via Ethernet | X | X | |

| Dyn. Run-Out, Spindle Vibrations and Resonance Speed Map | X | ||

| Axial Shaft Growth, Temperature and Spindle Speed with Time | X | ||

| FFT Impulse Response | X | ||

| Digital Drag Pointer Dial Gauge (Cap. Gauges) | X | X | |

| Spindle Error Analysis (SEA), radial | X | ||

| Spindle Error Analysis (SEA), axial | X |

Modules

- Spindle Error Analysis (SEA, Error-Motion)

- Dyn. Tool Run-Out and Spindle Vibrations over Spindle Speed

- Resonances and Natural Frequencies Map

- Shaft Growth, Temperature and Spindle Speed over Time

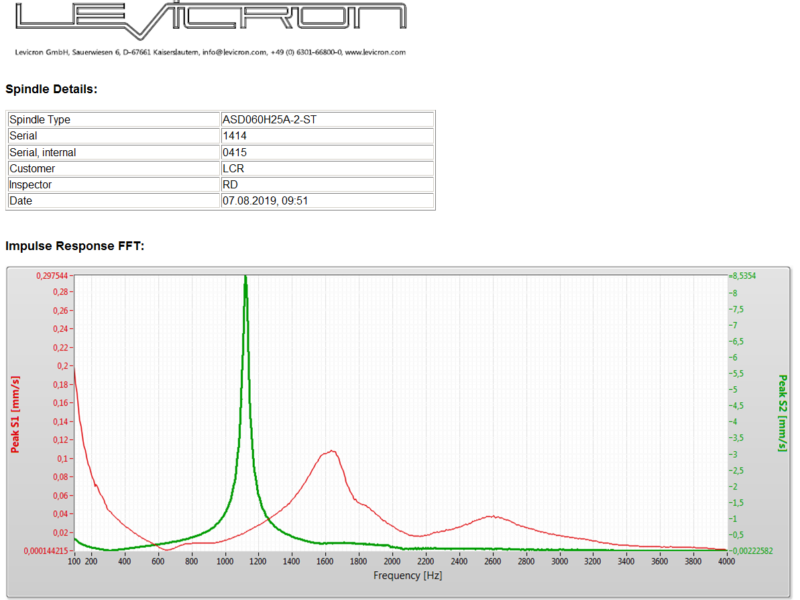

- 2-Channel-FFT with Peak-Hold (Impulse Response)

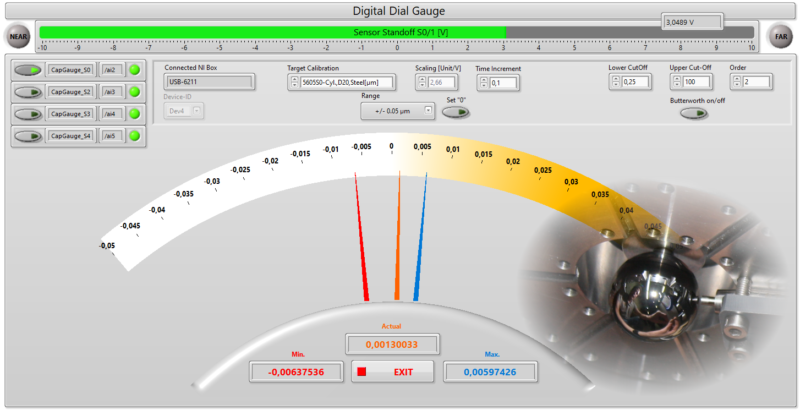

- 4-Channel Drag-Pointer Diag Gauge

- Spindle and Machine Tool Data Base

ShakesBear, Hamlet

The most significant deviation of the shaft spinning axis in radial or axial direction from an ideal axis is defined as Error-Motion. In this case, the ideal spinning axis has the lowest average overall measurements.

Spindle errors can be distinguished between synchronous and asynchronous where

- Synchronous Errors repeat with every rotation at the same shaft angular position and

- Asynchronous Errors are not repeatable between shaft rotations.

The Run-Out (fundamental) is a perfect spindle error polar plot circle and represents an off-centered tool. Thus run-out is not a spindle but a tool error.

Therefore the spindle error (Error-Motion) in the radial direction is defined as:

∑Sync.Errors + ∑Async.Errors – Fund. (run-out)

Direct (auto) error-separation:

Any measurement of radial spindle errors is taken against the spindle shaft or any object attached to it, preferably perpendicular to the equator of a precisely lapped sphere. However, any roundness error of the equator repeats with the shaft rotations and would be detected as a synchronous spindle error. Although there are methods to separate the target shape error from the spindle synchronous errors, those require two measurements and a change in set up in between two measures and are significantly error-prone.

By using at least three radially arranged distance sensors around the spinning axis, it is possible to separate spindle synchronous errors from the target shape errors by solving a complex transposed equation system before converting the signal back into the time domain. Levicron has included the direct error separation into their SEA treatment so that synchronous, asynchronous, and target shape errors can be measured and separated in one setup and a single measurement.

ShakesBear, Othello

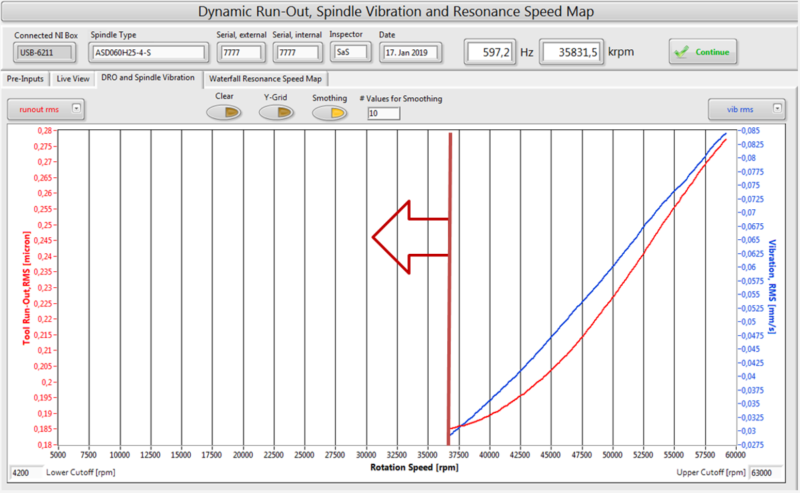

The included low-noise capacitive distance sensor with 2 nm resolution and 100 kHz sampling rate allows a sound measurement of the tool run-out at spindle speeds of up to 100,000 rpm. At the same time, a piezo-mass accelerometer detects spindle vibrations. An external trigger or the laser-tacho gives the spindle speed to create a continuous dynamic run-out, and spindle vibrations chart over speed.

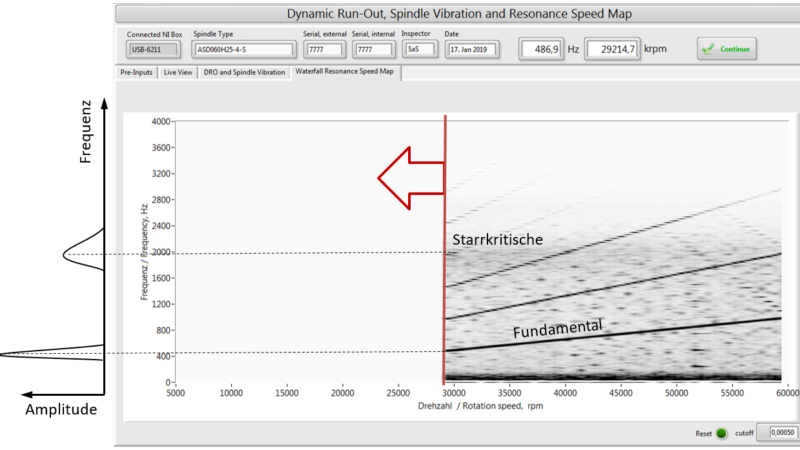

ShakesBear, Othello

Due to its high resolution and sampling rate, the capacitive distance sensor is capable of detecting the amplitude of the fundamental (spinning frequency) and any frequencies up to 4 kHz. As vibrations can be measured as a change in the distance, the capacitive gauge can be used to create an FFT spectrum at discrete spindle speeds. Changing the speed from stand-still to top speed, or vice-versa allows the creation of a continuous Waterfall-FFT chart where the single FFT charts are lined up and arranged with speed. The resonance speed map feature represents a 2.5-D Waterfall-FFT (looking top-down on a 3-D Waterfall diagram) where dark areas mean higher and light areas lower values. It allows the identification of spindle and system natural frequencies and resonances at which the fundamental (spindle frequency) crosses a natural system frequency.

When the capacitive gauge is used as the source, spindle frequencies are naturally measured dominantly. Using the included accelerometer instead gives natural frequencies of the entire system, including pumps, hydraulics, and chillers e.g. Placing the accelerometer anywhere in the system can thus be used as a tool to identify natural system frequencies with the spindle as a vibration source

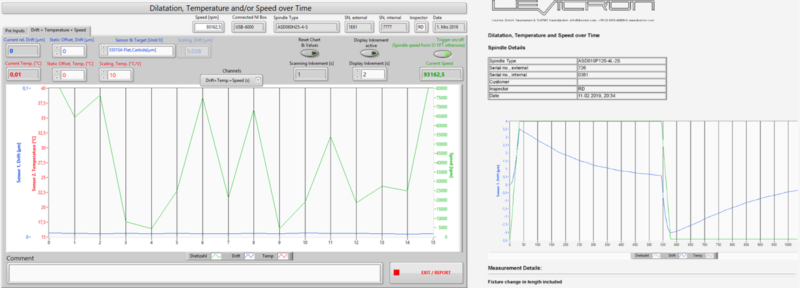

ShakesBear, Othello

When used axially against the spindle shaft, the capacitive gauge measures the thermal shaft growth with time. Along with an optional temperature sensor, which can be placed on any part of the machining system, the thermal shaft growth, temperature and spindle speed can be measured with time where the spindle speed can be detected using either an external trigger or the included laser-tacho.

ShakesBear, Othello

Using the included accelerometers or cap gauges, the FFT module offers an easy-to-use tool to measure and display the vibration amplitudes of the frequency spectrum and thus identify spindle or system natural frequencies while running the spindle or as a response to an impulse (Dirac Impulse). A Dirac-Impulse, also known as step response, can be re-assembled as the sum of all harmonics within the frequency spectrum. It means that a gentle hit at the spindle nose or anything in the system would excite all frequencies; thus, the spindle or the entire system would respond with larger amplitudes at its natural frequencies.

ShakesBear, Hamlet & ShakesBear, Othello

To set up the stand-off of the included cap gauges and to radially align the spindle artifact, the cap gauges measure against the included 4-channel, digital drag-pointer dial gauge can be used.

It can also be used to measure the static run-out of the artifact when turning the spindle by hand or at low speeds.

ShakesBear, Hamlet & ShakesBear, Othello

For an ISO certification in particular, but also for tracking the quality of the spindle products for internal use or customers, all measurements and results must be recorded and stored electronically. For this, our ShakesBear Software is designed to work with server systems. It is also based on a spindle or machine tool database in which all reports and rat data are stored . Whether connected to a server or working locally, the database module generates a folder structure for each serial number in which all reports and raw data are stored that can be recalled at any time