To run and use a motor spindle not only the spindle itself is required, but also accessories like a cable set, a spindle mount, a chiller or a drive.

To provide our customers with the best solution we have tested and assorted accessories that work the best with our spindle solutions. With every spindle from Levicron the customer gets recommendations of what is required to operate the spindle, or he can just order any recommended accessory from the list below.

Simply Put: “Ultra-Precision meets Industrial Grade“

Cable Sets

Cable Sets with connectors to the spindle, but open wires at the other end can be offered to any spindle from us. To operate the spindle on a specific spindle drive, or in combination with a motor filter, just let us know the drive model or just send us the drive connector with the pin configuration to prepare a cable set for you.

Get in touch with us to get the right cable solution for you!

Motor Filters

Motor Filters are used for several reasons. Spindle drives (converter drives) generally work with re-sampling the sinusoidal current to the motor phases from an inverter circuit (PWM). The higher this PWM frequency the lower the difference from the digital signal to the perfect sinusoidal waveform. However, this difference in current causes electrical losses that get larger the higher the spindle speed or the lower the PWM freuqncy of the converter. A Motor filter smoothes and lowers the overlaying current signal and thus lower the motor temperature. It also lowers the change in voltage with time (dU/dT) and beside a lower temperatur this can help to prevent the winding heads of the motor from getting damaged.

For our tool spindles ASD-H25, ASD-H25A and ASD-Cx we offer a motor choke (inductance) as a standard:

- 0.22 mH, 12 A Ieff for all motor options apart from “200 V high-torque”

- 0.3 mH, 18 A Ieff for motor option “200 V high-torque”

For our work-holding spindle ASD-Px we recommend a bespoke Sinus Filter.

Please contact us for the best motor filter!

Spindle Drives

The right spindle drive is the most sensitive accessory to a motor spindle. Of importance is not only performance, but robustness, signal quality, PWM frequency range, the right communcation protocols and that it is easy to set up and use. After an odyssey in the world of spindle drives we finally got in touch with company LTi and to our standard drive LTi Servo One as the most suitable drive solution for our spindles if not used in a CNC machine tool:

- LTi ServoOne SO84.20

- Standard Options::

- iPLC

- HF-Package

- TTL-out

However, with its synchronous motor and its 1 VSS SinCos rotary encoder our spindles can be operated on any external drive that supports synchronous motor technology. As there were:

- LTi ServoOne Junior

- Sieb&Meyer SD2S

- Sieb&Meyer FC72/80

- KEB F5

- Copley Xenus (only available for AC 200V)

As for CNC Machine tools the integrated spindle drive (converter) often can’t be used without the macine control we do not offer such drive systems. However, our spindles can be set up and operated on the following machine controls and drives without any issue:

- Fanuc (α-iSP11, α-iSP11HV)

- Heidenhain

- Siemens (6SL3120-1TE21-8AA1, 6SL3120-1TE24-5AA1 u.a.)

Chillers

Because of their strictly symmetrical spindle design and the integrated high-efficient thin-film liquid cooling our spindle solutions offer industry leading thermal stability.

It is obvious that the chiller contributes to thermal stability. For Ultra-Precision Machining we recommend a coolant temperature hysteresis of not more than 0.1°C and a vibration free collant pump. For CNC-machining it is recommenden to connect the machine and the spindle to the central chiller of the company.

For either application we have found chillers we could recommend or deliver with the spindle.

Just get in touch to get the right chiller with your Levicron spindle!

Spindle Mounts

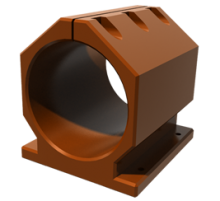

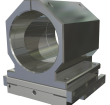

For horizontal operation of our spindles we can offer standard spindle mounts that can also be tailor made to your requirements. Only the spindle diameter has to be considered when changing centre height or foot print. Made from carbon steel and design for a reduced heat conductivity through its base our standard spindle mount allows a simple, robust, stiff and thermally neutral way to install our spindles in your machine.

The standard spindle mount for our ASD-H25, ASD-H25A und ASD-Cx has the following geometries (see picture to the right):

- Spindle Mount “112 x 106 x 70”:

- Foot Print Hole Pattern: 112 x 106 mm

- Centre Height: 70 mm (-20……+100 mm)

Hole pattern and centre height can be matched to your requirement. Please contact us for the right spindle mount to your application and machine!

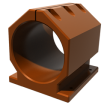

In the case the centre height needs to be adjustable (+/- 1 mm) we can offer an ultra-flat height adjuster with the spindle mount (see picture to the right)

Spindle Flanges

For the integration of our spindles into a vertical CNC machining center often a spindle flange for the axial connection is required. Shrink fit spindle flanges on the original spindle steel body has been proven to be a reliable, simple and cost-effective soluition that can be tailor made to match the Z-stock design of your machine.

For a higher volume also a custom spindle housing can be designed and machined.

Please let us know your requirements, we will look into the right flange design for you.

Stand-Alone Supply Cart

For an autonomous operation of our spindles a stand-alone supply cart can come with the spindle. This allows the use of one spindle on different machines and just requires AC voltage, compressed air and a chiller. Anything else like the drive, spindle control, air filtration or spindle safety is taken care of by the components installed in the supply cart.

Please refer to the Product Page for further information.