The right spindle for your industry. Our industry solutions at a glance:

Automotive

Automotive

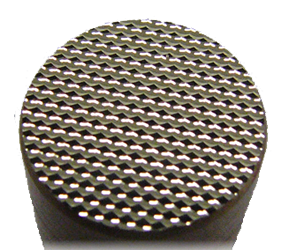

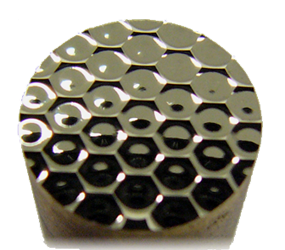

Especially for the automotive industry, LED lighting solutions are becoming increasingly important. Each LED cavity – and there can be hundreds in headlights – doesn’t only have to comply with the ultra-precision surface finish but also has to reflect the light emitted by the LED within a defined light cone and under a fixed angle.

Legal requirements for exhaust gas emission are getting tighter and tighter. A combustion engine found that the fuel injector is one of the parts with the most potential to optimize combustion. Herein the injection hole is the key feature, and the hole shape and surface finish the crucial properties. Thus high-speed spindles with a deficient error motion and low tool run-out are the key to manufacturing future fuel injectors.

We offer ideal tool spindle solutions with ultra-precision qualities and a stable high-speed operation for both applications and more.

Suitable spindle solutions:

Watch Industry

Watches

Most minor parts and the highest precision combined with mirror surface finish lead to the fact that Ultra-Precision Machining is required to manufacture mechanical watches. On the other hand, the volume requires highly productive CNC Machining with automated tool change. With our aerostatic tool spindle solutions, ASD-H25 and ASD-H25A, we offer a perfect solution to what is needed in the Swiss Watch Industry. Besides their ultra-precision qualities and high spindle speed, even “Guillochage” (unique engraving technique) can be done because of the spindle robustness and the integrated rotary encoder. Because of their integrated synchronous motor technology and much higher torque at lower speeds tapping holes can be done much faster than with other spindle solutions.

For machining components for the most famous Swiss watches, our tool spindle solutions are used with great success and results this industry never reached before.

Suitable spindle solutions:

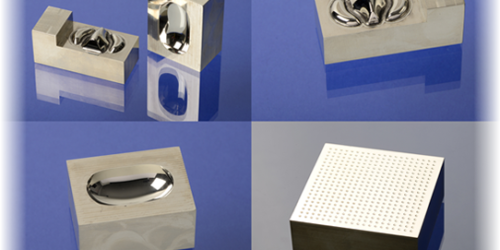

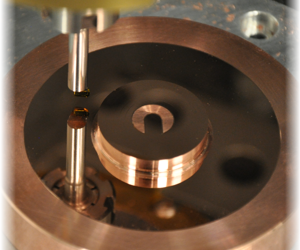

Coining Dies and Engravings

Coinage and engraving

Coining Dies are made from tool steels like STAVAX e.g., Heat treatment must occur before machining, which makes grinding the proper machining process. However, very small features and engravings only leave milling with carbide or CBN tools as a machining process. As machining can take days, a high spindle speed is required to increase productivity and a stable spindle solution even at a high rate over days. Our aerostatic spindle solutions don’t change their properties with time and run at very high speed at a dynamic tool run-out of under 1 micron. They are the idal spindle solutions for this application.

Suitable spindle solutions:

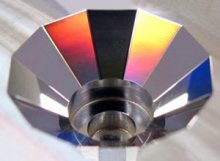

Lighting Industry

Lighting

LED Lighting requires machining the LED cavity to reflect the light efficiently and in a defined light cone. It means that there is not only

ultra-precision machining needed to achieve sub-micron accuracies and nanometer surface finish but also automated robust machining is also usual for CNC Machining.

As our aerostatic spindle solutions are ultra-precise, offer CNC functionality with HSK tooling, and give speed and robustness to machine dies and components for LED lighting.

Matching spindle solutions

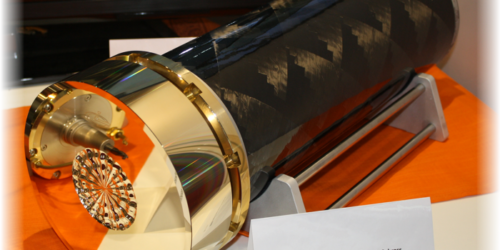

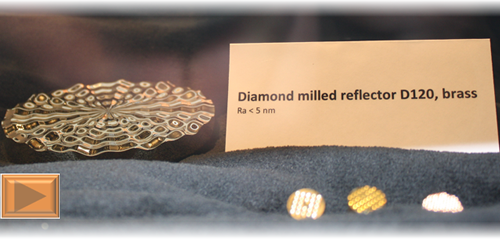

Technical Optics

Optical technologies

Precision Optics used in telescopes, microscopes, or exposure units require ultra-precision turning, milling, and grinding to achieve sub-micron geometries and nanometer surface finish. Besides the grinding of glass lenses with drastically reduced sub-surface damage, ultra-precision turning and milling of optical components are the most common machining technology with our tool and work holding spindles. As it affects the form accuracy, polishing often is not allowed, and the part needs to be used as it comes from the lathe or the machine tool.

Suitable spindle solutions:

Electronic Components

Electronic components

The integration of functions and electrical circuits requires modern and future electronic components to be small and precise at the same time. An example is fiber optics, where the optical fiber at the connector must be aligned with 1 micron.

What are the properties of an ideal spindle to electronic machine components? Besides the technical and electrical design, manufacturing and material properties seem to become the bottleneck of further miniaturization. For tool and work holding spindles, besides increased speeds, accuracy and stability are crucial to keeping up with the current trend in the electronics market.

- High Spindle Speeds

- Dynamic and Thermal Stability even at top speed and long machining cycles

- Stable Properties even for long machining cycles

- Automated Tool Change

Suitable spindle solutions: