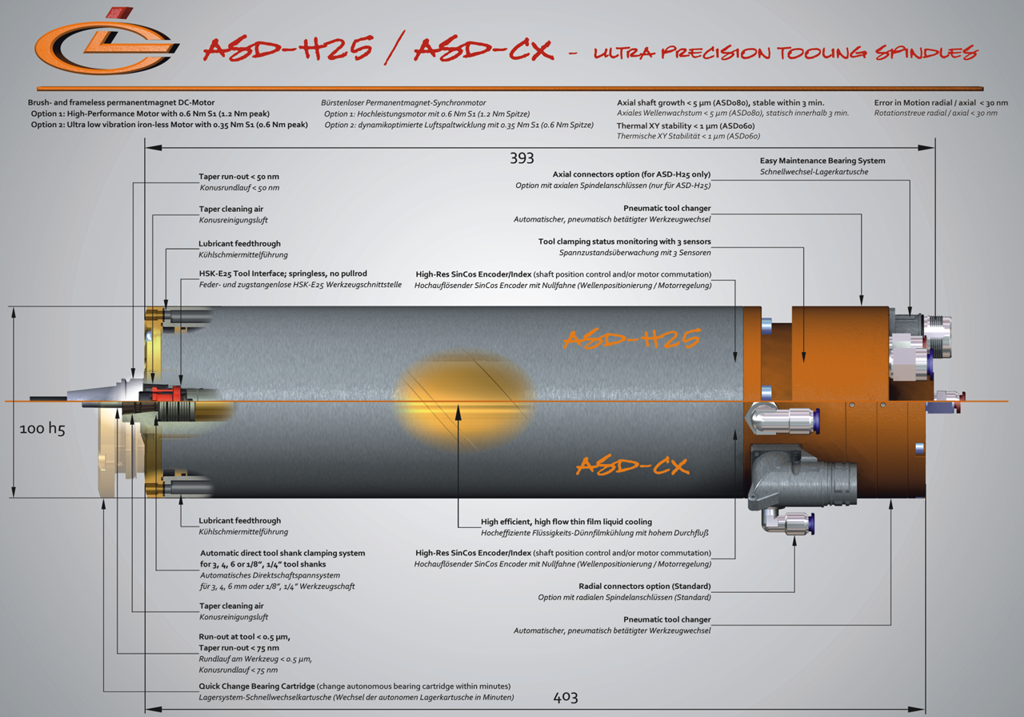

About the “ASD-Cx/ UASD-Cx”

with radially oriented spindles connectors

- High speeds for micromachining up to 100,00 rpm

- Low error motion values for the machining of optical components

- Also available with a high-pressure aerostatic bearing system (UASD-Cx)

- Features an automatic precision collet system

Our spindle solutions ASD-Cx/ UASD-Cx (x = tool shank diameter) combine ultra-precise spindle qualities for generating optical surfaces with the robustness and functionality of current tool spindles for CNC machining. The models are equipped with a self-developed and automatic precision collet system and thus allow the highest speeds up to 100,000 rpm. These are paired with the highest precision tool clamping with guaranteed static concentricity on the tool of less than 0.5 µm TIR. The high-resolution turning encoder developed in-house, with efficient thin-film liquid cooling and a steel housing with a standardized diameter, is also used here. In addition, it guarantees flexibility, maximum thermal stability, and high material removal rates thanks to high spindle stiffnesses and load capacities.

As a result, the user gets unprecedented precision, thermal stability, and the ability to machine optical surfaces in milling and grinding applications for ultra-precision machining or CNC applications.

As a result, the user gets unprecedented precision, thermal stability, and the ability to machine optical surfaces in milling and grinding applications for ultra-precision machining or CNC applications.

– Ultra-precise aerostatic tool spindle with auto collet tool clamping

ASD-Cx

Our collets offer a unique static runout of guaranteed 0.5 µm on the tool. The design and manufacture of the product take place in-house. As standard, our ASD-Cx is matched and optimized to one collet.

On the customer’s request, the installed collet can be exchanged for one with a different clamping diameter by the customer. The following clamping diameters are available for this purpose:

- 6 mm, 4 mm, or 3mm

- 1/4″ and 1/8″.

ASD-CLT

Some important applications, such as contact lens turning, require clamping 1/2″ (12.7 mm) shanks. Until now, the integrated automatic precision collet could cover tool shanks up to 1/4″ (see left). Based on a proven design, our ASD-Cx is now available for clamping 1/2″ shanks to hold block pieces needed for machining contact lenses, for example.

The new collet design features the following clamping diameters:

- 1/2″ (12.5 mm (0.49″) to 13 mm (0.51″))

- ASD-Cx/ UASD-Cx at a glance

- ASD-Cx und UASD-Cx (with high-pressure aerostatics) in comparison

- As Download

- Video

| Body diameter | 100 mm |

| Lenght | 395 mm / 415 mm |

| Weight | 16 kg |

| max. Speed | 60,000 rpm/ 80,000 rpm/ 100,000 rpm *) |

| Tool interface | Präzisionsspannzange, pneumatisch betätigt |

| Available clamping diameters | 100 mm |

| Spindle connectors | 1/4", 1/8", 6 mm, 4 mm, 3mm, 1/2" |

| Motor options | 400 V max., "High-power", 0.7 Nm S1 / 200 V max., "High-power", 0.7 Nm S1 |

| 400 V max., "Iron-less", 0.33 Nm S1 / 200 V max., "Iron-less", 0.33 Nm S1 | |

| Angular position control | 1 VSS SinCos, 80 lines, zero-flag |

| Tool change system | pneumatic, taper cleaning air |

| Spindle cooling | thin-film liquid cooling |

| Bearing system | aerostatic (ASD-Cx)/ high-pressure aerostatic (UASD-Cx) |

| Accuracy, Dynamics | dynamic tool run-out < 0.5 µm **) |

| shaft error in motion) < 30 nm | |

| *) other spindle speeds on request |

Like our ASD-H25 or ASD-H25A with springless HSK-E25 tool clamping, our ASD-Cx with direct shaft clamping is also available as a high-pressure aerostatic variant (UASD-Cx). With a bearing pressure of 20 – 30 bar, this achieves a load capacity increase of 300% in both axial and radial directions and offers a significant increase in robustness in addition to the resulting unchanged dynamic and accuracy values.

| ASD060Cx | UASD060Cx | ||

| Bearing air supply pressure | [bar] | 6 - 10 | 20 - 30 |

| Speed | [rpm] | 0 - 60,000 | 0 - 60,000 |

| Static radial ult. load capacity at spindle nose | [N] | 330 | 900 |

| Static ult. load capacity | [N] | 550 | 1,300 |

| Static radial stiffness at spindle nose | [N/µm] | 41 | 83 |

| Static axial stiffness | [N/µm] | 60 | 75 |

| Static air consumption | [Nl/min] | 50 | 90 |

| Dynamic tool run-out **) | [µm] | < 0.4 | < 0.3 |

| Shaft error in motion **) | [nm] | < 23 | < 28 |

| *) all values are taken at 20 bar aur supply pressure |