What do you need for a simple, safe, and consistent Hollow-Taper-Shank tool clamping (HSK)?

Nothing more than this …

Problem

Tool spindle manufacturers know of all the problems with a spring-based taper clamping system – a complex and stacked design combined with inconsistent balancing and shaft dynamics, spring fatigue, inconsistent clamping positions, and pull-in forces at excessive servicing.

On the other hand, existing self-locking clamping systems appear too complex and show quite different problems. Due to the serial combination of several taper connections, these clamping systems not only cover a broad travel range but also suffer from clamping position and pull force due to non-predictable changes in tribological conditions. Self-locking taper clamping systems that comply with the current state of the art also use a self-locking unit connected to a standard clamping unit which can be used with other clamping systems. It again affects the already significant change in clamping position.

Our solution:

Our newly developed and patent pending spring-less automatic clamping system for Hollow-Taper-Shank (HSK) tools with optional aerostatic rotary feedthrough is based on the principle of a monolithic pre-loaded self-locking. For this, the clamping and the locking unit used with other spring-less clamping systems are combined and reduced to only one single unit of a very simplistic design that covers the clamping as well as the self-locking.

The results for the spindle manufacturer:

- The number of parts involved reduces to the minimum

- Ultra-compact, simple and light design

- clamping system removable (service) from the shaft without removing it from the spindle

- Non-rotating drawbar (standard)

- Forces to eject a tool reduced by 60 % (to preserve the spindle bearings)

- Optional aerostatic rotary feedthrough (not available for SLH-25)

The benefits of your machining application:

- Consistent clamping force and positions even over 2 million tool change cycles

- Consistent and excellent shaft balancing and dynamics

- Especially for spindle solutions that are meant to machine optical components

- Higher spindle speeds

- Greatly improved reliability

- Maintenance-free

| Type | [-/-] | SLH20 |

| Interface | [-/-] | HSK-E20, DIN 69893-5 |

| Max. Speed | [rpm] | 150,000 |

| Operating Force, Clamping | [N] | 400 |

| Operating Force, Release | [N] | >= 400 |

| Pull-In Force | [N] | 1,900 - 2,500 |

| Clamping Travel without tool from Eject Position *) | [mm] | 3.7 |

| Nominal Clamping Position (N) | [mm] | 2.5 |

| Eject Travel (A) from (N) | [mm] | 2.7 |

| Travel from (N) without Tool (B) | [mm] | 1.7 |

| Bore Diameter (D) | [mm] | 10.5 H4 |

| Overall Length (L) | [mm] | 45 |

| Connection Thread (G) | [-/-] | M5x0.5H LH |

| Guide Bore Diameter (d) | [mm] | 5.2 H5 |

| Rotary Feedthrough (optional) | [-/-] | No |

*) at 0.2 mm axial gap; limited by piston pack

| Type | [-/-] | SLH25 |

| Interface | [-/-] | HSK-E25, DIN 69893-5 |

| Max. Speed | [rpm] | 90,000 |

| Operating Force, Clamping | [N] | 700 |

| Operating Force, Release | [N] | >= 800 |

| Pull-In Force | [N] | 3,500 - 5,000 |

| Clamping Travel without tool from Eject Position *) | [mm] | 4.9 |

| Nominal Clamping Position (N) | [mm] | 3 |

| Eject Travel (A) from (N) | [mm] | 3.1 |

| Travel from (N) without Tool (B) | [mm] | 1.8 |

| Bore Diameter (D) | [mm] | 13.3 H4 |

| Overall Length (L) | [mm] | 54 |

| Connection Thread (G) | [-/-] | M6x0.75 6H LH |

| Guide Bore Diameter (d) | [mm] | 6.3 H5 |

| Rotary Feedthrough (optional) | [-/-] | No |

*) at 0.2 mm axial gap; limited by piston pack

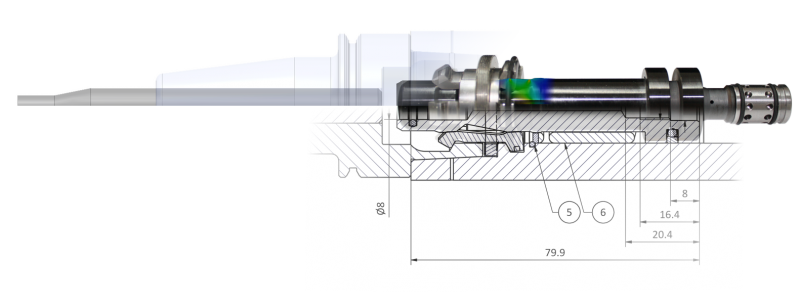

Operation, General Arrangement and Shaft Internal Contour

| Type | [-/-] | SLH32 |

| Interface | [-/-] | HSK-E32, DIN 69893-5 |

| Max. Speed | [rpm] | 80,000 |

| Operating Force, Clamping | [N] | 900 |

| Operating Force, Release | [N] | >= 1,000 |

| Pull-In Force | [N] | 6,500 -8,000 |

| Clamping Travel without tool from Eject Position *) | [mm] | 6 |

| Nominal Clamping Position (N) | [mm] | 4 |

| Eject Travel (A) from (N) | [mm] | 4.2 |

| Travel from (N) without Tool (B) | [mm] | 1.8 |

| Bore Diameter (D) | [mm] | 16.8 H4 |

| Overall Length (L) | [mm] | 69 |

| Connection Thread (G) | [ -/- ] | M6x1 6H LH |

| Guide Bore Diameter (d) | [mm] | 6.4 H5 |

| Rotary Feedthrough (optional) | [ -/- ] | No |

*) at 0.2 mm axial gap; limited by piston pack

Operation, General Arrangement and Shaft Internal Contour

| Type | [-/-] | SLH40 |

| Interface | [-/-] | HSK-E40, DIN 69893-5 |

| Max. Speed | [rpm] | 60,000 |

| Operating Force, Clamping | [N] | 2,100 |

| Operating Force, Release | [N] | >= 2,000 |

| Pull-In Force | [N] | 7,500 - 10,000 |

| Clamping Travel without tool from Eject Position *) | [mm] | 7.3 |

| Nominal Clamping Position (N) | [mm] | 3.85 |

| Eject Travel (A) from (N) | [mm] | 4.3 |

| Travel from (N) without Tool (B) | [mm] | 3.1 |

| Bore Diameter (D) | [mm] | 21 H4 |

| Overall Length (L) | [mm] | 83.7 |

| Connection Thread (G) | [ -/- ] | M8x1 6H LH |

| Guide Bore Diameter (d) | [mm] | 8.5 H5 |

| Rotary Feedthrough | [ -/- ] | optional |

*) at 0.2 mm axial gap; limited by piston pack

Operation, General Arrangement and Shaft Internal Contour

| Type | [-/-] | SLH63 |

| Interface | [-/-] | HSK-E63, DIN 69893-5 |

| Max. Speed | [rpm] | 40,000 |

| Operating Force, Clamping | [N] | 6,000 |

| Operating Force, Release | [N] | >= 6,500 |

| Pull-In Force | [N] | 23,000 - 35,000 |

| Clamping Travel without tool from Eject Position *) | [mm] | 10.2 |

| Nominal Clamping Position (N) | [mm] | 2.2 |

| Eject Travel (A) from (N) | [mm] | 8.0 |

| Travel from (N) without Tool (B) | [mm] | 4.5 |

| Bore Diameter (D) | [mm] | 33 H4 |

| Overall Length (L) | [mm] | 136 |

| Connection Thread (G) | [-/-] | M10x1.5 6H LH |

| Guide Bore Diameter (d) | [mm] | 10.5 H5 |

| Rotary Feedthrough (optional) | [-/-] | Yes |

*) at 0.2 mm axial gap; limited by piston pack