All of our tool spindle solutions combine CNC functionality with Ultra-Precision. Together with the patented bearing technology and our highly specialized production we can offer high-speed tool spindle solutions for the production of optical components and high-precision parts with industrial tool clamp and tool change function, tool clamp status monitoring, high-efficient liquid cooling and cutting fluid feed through.

With their HSK-E20, HSK-E25, HSK-E32, HSK-E40, and HSK-A63 tool interface our spindle solutions comply with DIN 69893 and offer unique solutions for CNC Milling, Turning and Grinding with standardized spindle diameters 80, 100, 120 and 175 mm.

- ASD-Cx / UASD-Cx

- ASD-H20A / UASD-H20A

- ASD-H25 / UASD-H25

- ASD-H25A / UASD-H25A

- UASD-H32 / UASD-H32A

- UASD-H40A

- ASD-PH63M

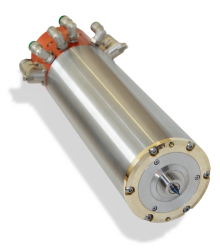

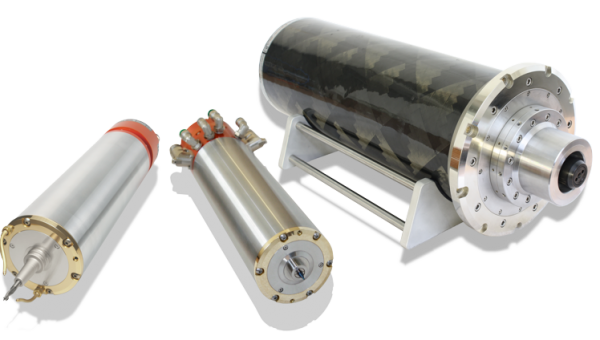

- Patented Aerostatic Bearing Technology (ASD-Cx)

- Patented High-Pressure Aerostatic Bearing Technology (UASD-Cx)

- Spindle Ø 100 mm

- Radially oriented spindle connectors

- Precision Auto Collet (3 mm, 4 mm, 6 mm, 1/8″, 1/4″)

- 60.000, 80.000 and 100.000 rpm

- Synchron Motor Technology, “High-Torque” (0.7 Nm) and “Ultra-Precision” (0.35 Nm) Option

- Tool Clamp Status Monitoring

- High-Efficient Thin-Film Liquid Cooling

- Error-Motion: < 30 nm

- Patented Aerostatic Bearing Technology (ASD-H20A)

- Patented High-Pressure Aerostatic Bearing Technology (UASD-H20A)

- Spindle Body Ø 80 mm

- Axially oriented spindle connectors

- Automatic, pring-less HSK-E20 tool interface

- Available Speeds: 120,00 and 150,000 rpm

- Tool Clamp Status Monitoring

- Thin-Film Liquid Cooling

- Error-Motion: < 40 nm / < 45nm

- Patented Aerostatic Bearing Technology (ASD-H25)

- Patented High-Pressure Aerostatic Bearing Technology (UASD-H25)

- Spindle Body Ø 100 mm

- Radially oriented spindle connectors

- Automatic, spring-less HSK-E25 tool interface

- Available Speeds: 60,000, 80,000 and 90,000 rpm

- Synchron Motor Technology, “High-Torque” (0.7 Nm) or “Ultra-Precision” (0.35 Nm) Option

- Tool Clamp Status Monitoring

- Thin-Film Liquid Cooling

- Error-Motion: < 30 nm

- Patented Aerostatic Bearing Technology (ASD-H25A)

- Patented High-Pressure Aerostatic Bearing Technology (UASD-H25A)

- Spindle Body Ø 100 mm

- Axially oriented spindle connectors (Dmax 100 mm)

- Automatic, spring-less HSK-E25 tool interface

- Available Speeds: 60.000, 80.000 and 90.000 rpm

- Synchron Motor Technology, “High-Torque” (0.7 Nm) or “Ultra-Precision” (0.35 Nm) Option

- Tool Clamp Status Monitoring

- Thin-Film Liquid Cooling

- Error-Motion: < 30 nm

- Patented High-Pressure Aerostatic Bearing Technology (UASD-H32/A)

- Spindle Body Ø 100 mm

- Radially and axially oriented spindle connectors

- Automatic, pring-less HSK-E32 tool interface

- Available speeds: 60,000 and 80,000 rpm

- Synchron Motor Technology, “High-Torque” (0.7 Nm) or “Ultra-Precision” (0.35 Nm) Option

- Tool Clamp Status Monitoring

- Thin-Film Liquid Cooling

- Error-Motion: < 35 nm

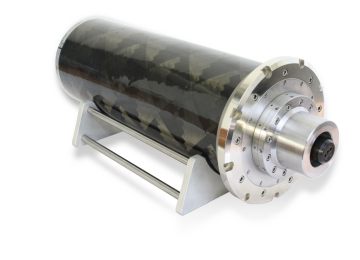

- Patented High-Pressure Aerostatic Bearing Technology (UASD-H20A)

- Ult. Radial Load Capacity: 3.000 N at Spindle Nose

- Ult. Axial Load Capacity: 5.000 N

- Spindle Diameter Ø 120 mm

- Axially oriented spindle connectors

- Automated spring-free HSK-E40 Tool Interface

- Max. 60.000 rpm

- Synchron Motor Technology, 4 Nm S1/100%

- Analog Tool Clamp Status Monitoring

- High-Efficient Thin-Film Liquid Cooling

- High-Pressure aerostatic Shaft Feed Through for cutting fluid

- Error-Motion: < 40 nm

- Patented Aerostatic Bearing Technology

- Spindle Ø 175 mm, Flage Ø 225

- HSK-A63 tool interface, manual

- 10.000 rpm, 12.000 rpm

- Synchron Motor Technology, “High-Torque” (13 Nm) and “Ultra-Precision” (6 Nm) Option

- High-Efficient Thin-Film Liquid Cooling

- Error-Motion: < 15 nm