News and Updates // World’s first Ultra-Precision HSK Tool Holders “UTS-x” from Levicron

- January 24, 2015

- Posted by: Levicron

- Category: News and Updates, Trade Shows

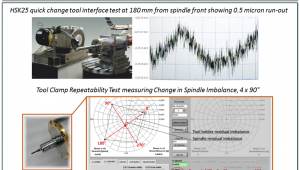

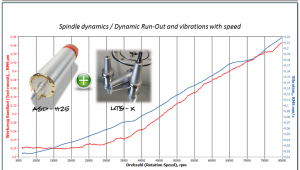

Commercially availably HSK tool holders are specified with a run-out at the tool < 3 mic and a balance quality of < G2.5 mm/s at 25.000 rpm according to the German DIN69896. Up until now no spindle solution existed with which these numbers could be verified. However Levicron’s tool spindle models ASD-H25 and ASD-H25A are specified with a taper run-out of < 50 nm, a tool clamp repeatability of < 0.2 mic and a balance quality of < G0.05 at 60.000 rpm. Comparing these numbers it becomes obvious that using standard HSK tool holders with our spindles doesn’t meet with the requirements for Ultra-Precision Machining.

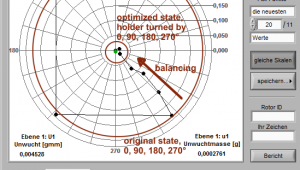

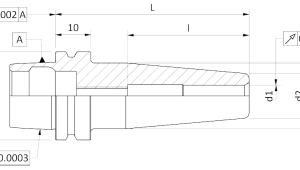

Because of this Levicron decided to develop a better solution with their tool holder series UTS-x. A balance quality of < G 0.3 mm/s at 60.000 rpm (25 times better than industry standard) and a run-out at tool of < 0.8 mic (3 times better than the industry standard) now enables ultra-precision machining with HSK-E25 tooling.

At a glance:

- Balance Quality: G 0.3 mm/s at 60.000 rpm

- Run-Out at Tool: < 0.8 mic

- Repeatability: < 0.2 mic

- Clamping: Thermal Shrinking

- Tool Shank Sizes: 6 mm, 4 mm, 3 mm, 1/4″, 1/8″

And of course, Levicron uses their own tool spindles to machine, hold and balance their UTS-x tool holders.

ADDITIONAL INFORMATION

Get more information at our Products Page about our ultra-precision tool holder series as well as custom holders!

DETAILS

| What: | Levicron introduces their ultra-precision tool holder series UTS-x |

|---|---|

| When: | January 2015 |

| Where: | -,- |

Leave a Reply

You must be logged in to post a comment.