Newsletter // April 2014

- April 10, 2014

- Posted by: Levicron

- Category: News and Updates, Newsletter

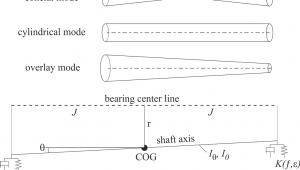

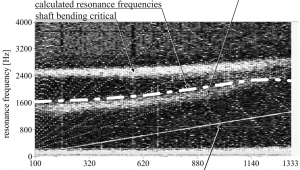

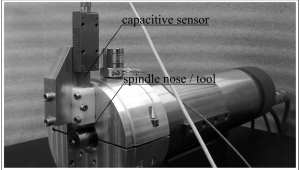

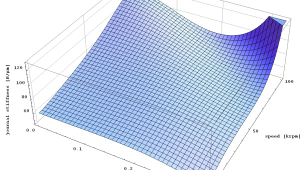

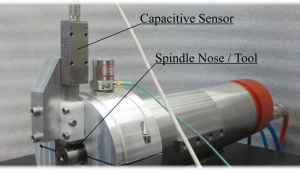

What surprises most customers and other spindle manufacturer is the design goal of all our spindle solutions – a spindle operation below any spindle resonance from standstill to top speed. This newsletter explains the change in stiffness with speed for an aerostatic high-speed spindle depending on speed and temperature and why spindle solution from Levicron manage it to stay even below the rigid mode resonance frequencies. For the user this means he can use the spindle over its entire speed range without the “sweet spots” he normally needs to use with other tool spindles, doens’t matter if aerostatic or conventional. But this also means that the bearing stiffness of Levicron spindles are much higher than others.

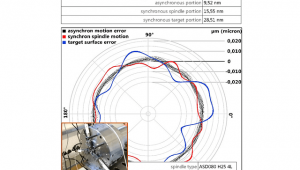

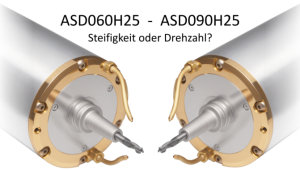

What is brought up by most cusomters is the question about speed and stiffness. In this newsletter we directly compare our ASD060H25 (60.000 rpm) with our ASD090H25 (90.000 rpm) and give recommendations when the applications requires the one or the other.

With additional encoder and work-holding options our work-holding spindle ASD-Px now offers more to the customer. Beside a second hi-res optical encoder to improve the angular position accuracy the user now can hold the qork piece with a zero-point chuck.

Refer to the PDF to get more information.

Newsletter Content:

- Valid for all of our spindle solutions: Operation below any spindle resonance frequencies, from standstill to top speed

- The crucial question: Higher speed or higher stiffness – ASD060H25 vs. ASD090H25

- Work holding spindle ASD-Px now available with second hi-res encoder option and zero-point chuck

- Upcoming trade shows

ADDITIONAL INFORMATION

Subscribe to our newsletter …

DETAILS

| What: | Levicron Newsletter |

|---|---|

| When: | April 2014 |

| Where: | -,- |

Leave a Reply

You must be logged in to post a comment.