ShakesBear // Fully automated and Nanometer Level Spindle Error Analysis (SEA, ISO 230-7)

- March 21, 2022

- Posted by: Ralf Dupont

- Category: Applications, News and Updates, Newsletter

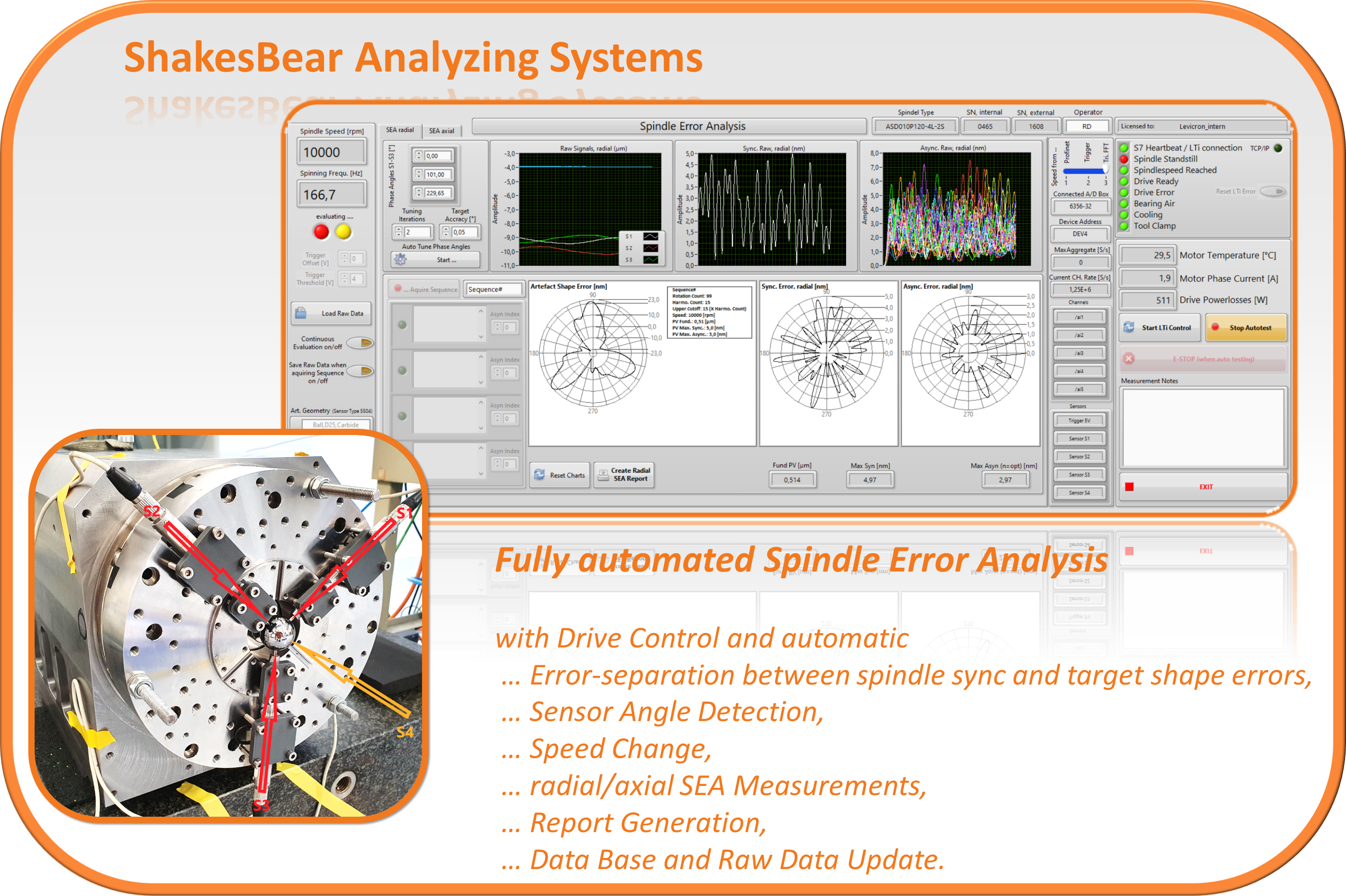

It’s been a long way, but we have finally completed our fully automated Spindle Error Analysis Project based on our ShakesBear Analyzers. Full drive control, automatic speed changes, measurements, reports and data base updates combined with closed loop safety monitoring. Currently for our increasing internal requirements, but should you be interested, we are happy to hearing from you.

With the drive connected to a Siemens S7 running an OPC Server our Analyzing software is able to control the drive using an OPC client and does speed changes, measurements, reports and data base updates all by itself.

Fully automated Spindle Error Analysis (SEA) on a nanometer level and for speeds of up to 100.000 rpm.

Just set up and adjust the sensors, anything else happens automatically.

- Safety closed loop covering coolant, bearing air, drive errors, drive and moto data,

- Sensor angle detection,

- Error-separation between spindle sync. and target shape errors,

- Speed changes,

- Measurements and raw data storage,

- Reports and data base updates.

We (I) just love this thing.

Read more about our ShakesBear Spindle and Machine Analyzers