Application // Laser Reflector Machining, D120, 80.000 rpm

- March 15, 2015

- Posted by: Levicron

- Category: Applications, News and Updates

No Comments

SUBJECT

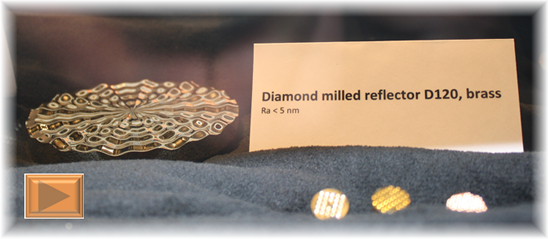

For an accurate deflection of laser beams freeform mirros with a surface finish of better 10 nm Ra are required. Presented machining example shows the freeform creation of such a reflector based on a polynomial function. A Levicron tool spindle type ASD080H25 on an ultra-precision machining center with slow-tool servo function and a diamond ball end mill R2 were used.

Rough cutting was done with a standard carbide tool at 80.000 rpm, 1 mm cutting depth and 0.4 mm feet rate per cutting edge. Rough cutting time: 45 min. Finish cutting was done at 5 micron cutting depth and 5 micron feedrate per cutting edge at 80.000 rpm. Finish cutting time: 24 h.

Achieved surface finish: 7 nm Ra

CONTENT

- Laser Reflector Machining, Material MS58, D 120 mm

- Machine: LT-Ultra MTC (UP, 3 Axes, Slow-Tool Servo Mode)

- Tool Spindle: Tool Spindle: Levicron ASD080H25

- Tooling, Roughing: Carbide Ball End Mill, D4

- Infeed, Roughing: 1 mm depth, 0,5 mm feedrate per cutting edge and revolution

- Rough Machining Time: 45 min

- Tooling, Finishing: Natural Diamong Ball End Mill, D4

- Infeed, Finishing: 5 micron depth, 5 micron feedrate per cutting edge and revolution

- Finish Cutting time: 24 h

- Achieved Surface Finish: < 7 nm Ra

ADDITIONAL INFORMATION / VIDEO

DETAILS

| Client: | Confidential |

|---|---|

| Hardware: | LT-Ultra MTC + Levicron ASD080H25 |

| Contact: | Ralf Dupont, Levicron |

| Date: | March 2015 |

Leave a Reply

You must be logged in to post a comment.