Application // Laser Reflector Manufacturer in Steel

- April 25, 2013

- Posted by: Levicron

- Category: Applications, News and Updates

No Comments

GEGENSTAND

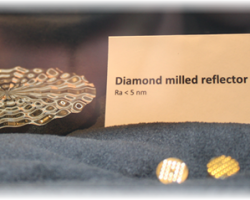

For an accurate deflection of laser beams mirrors are required. This example shows the machining of a laser reflector mold in steele based on a polynomial function.A 3-axis ultra-precision machine tool with slow-tool servo function (rotary axis synchronized with linear axes) and our ASD080H25 with a CBN tool D 3 mm were used.

Goal was to minimize machining time at a fixed maximum surface finish. Rough machining was done at 0.3 mm cutting depth and 0.2 mm feed rate per cutting edge and revolution. Finish machining was done at 10 micron cutting depth and feed rate. Overall machining time: 2 h. Surface finish: < 20 nm Ra.

INHALTE

- Material: 1.2080, HRC58

- Machine: LT-Ultra MTC (3 axes, slow-tool servo)

- Spindle: Levicron ASD080H25 at 80.000 rpm

- Tool, roughing: Standard carbide ball end mill, D3

- Cutting depth, roughing: 0.3 mm

- Tool, finishing: CBN ball end mill, D3

- Cutting depth, finishing: 10 mic

- Overall machining time: 2 h

- Achieved surface finish: 18 nm Ra

ADDITIONAL INFORMATION

DETAILS

| User: | Confidential |

|---|---|

| Hardware: | LT-Ultra MTC + Levicron ASD080H25 |

| Direct Contact: | Ralf Dupont, Levicron |

| Date: | April 2013 |

Leave a Reply

You must be logged in to post a comment.