Application // Chip Removal Process during Lenslet Creation

- June 27, 2014

- Posted by: Levicron

- Category: Applications, News and Updates

GEGENSTAND

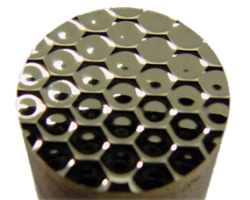

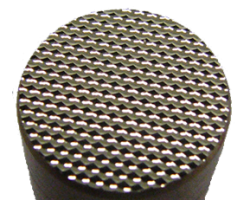

Lenslet Arrays are used for a directional reflection of light or laser beams to create a defined constant or transient light pattern. Hence requirements on form and surface finish are very high. By using ultra-precision machine tools and spindles, natural diamont tools and complex machining methods lenslets can be machined with a form accuracy of below 50 nm and a surface finish of under 5 nm Ra.

Precitech, Vision Research and Levicron together set up a lenslet creation process toegther with a high-speed camera system to see details of how chips are removed. For the second video the spindle spins with 60.000 rpm, means 1.000 Hz, wehre the camera was working at 1.000 fps. For the viewer the tool doesn’t seem to rotate as rotation and the fps rate was perfectly synchronized.

CONTENT

- Tool path programming for circular lenslet creation

- Natural diamond tools for lenslet creation

- Ultra-Precision Machine Tool for optical lenslet machining

- Interferometry to verify lenslet quality

- Phantom F4 camera system from Vision Research at 1.000 fps

ADDITIONAL INFORMATION

Videos:

DETAILS

| User: | AMETEK Precitech Inc. |

|---|---|

| Hardware: | Precitech FreeForm TL, Levicron ASD080H25 |

| Direct Contact: | Dr. Jeff Roblee |

| Date: | April 2014 |