New product development // ShakesBear V3 – new version now available

- February 23, 2023

- Posted by: Anna-Lena Roiger

- Category: Applications, News and Updates

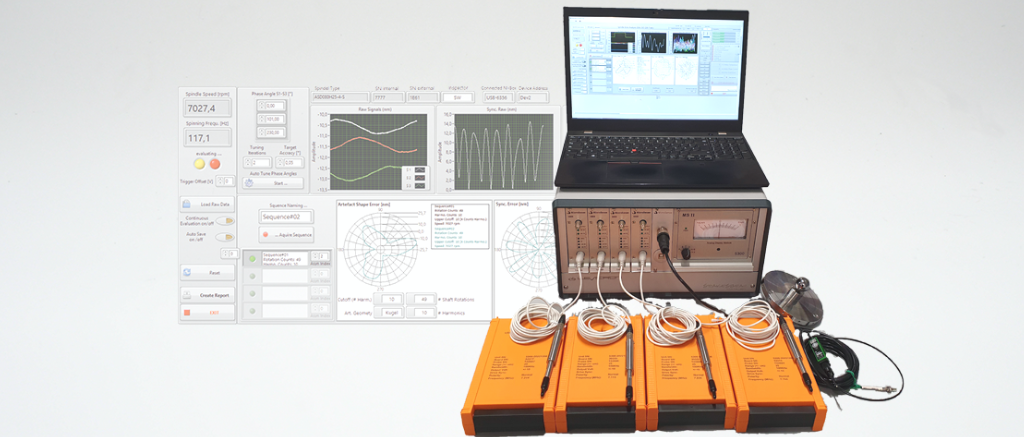

Spindle error analysis (error motion) according to ISO230-7 for ultra-precision spindles is complex. Resolutions of under 1 nm at speeds of up to 100,000 rpm require sophisticated hardware and software. Especially when it comes to automatically distinguish between spindle synchronous and shape errors of the target you measure against. Because it is repeatable with every rotation, such a shape error would actually be identified as spindle synchronous error. For these reasons and because such a system was not commercially available, we developed own solutions for internal use which we combined in out ShakesBear Software Suite. After realizing that there was quite a demand we made these available for our customers some tome ago.

Where the software “ShakesBear” is the same for all, we split the hardware based on their application and use into the “Hamlet” and “Othello” system. Where with the “Hamlet” system the user can do spindle error analysis (SEA) with sub-nanometer resolution and at speeds of up to 100,000 rpm, the “Othello” system is specialized in analyzing spindle and machine dynamics.

With the new ShakesBear version 3 we now have again combined all our knowledge in analyzing spindles and machines

- Spindle Error Anlysis (SEA) at nanometer reosultion and for speeds of up to 100,000 rpm (Hamlet)

- Dynamic tool run-out, spindle vibrations and resonance speed maps (spindle, machine) (Othello)

- Axial shaft growth and temperature with time and/or spindle speed (Othello)

- FFT analysis and impulse response (Othello)

- Digital Drag Pointer Dial Gauge (Hamlet, Othello)

With these testing methods, the user not only can qualify his or other spindle products but can also cover machine dynamic analysis with the spindle as exciting force. All measurements and product features are part of a system and product database, which are fully customizable by the user or us.

On our product page, you can find out which features, advantages, and benefits our ShakesBear systems “Hamlet” and “Othello” have.

DETAILS

| Topic | New product development |

|---|---|

| Date | February 2023 |

| Available from | immediately |

Subscribe our newsletter now: