Newsletter // January 2013

- January 17, 2013

- Posted by: Levicron

- Category: News and Updates, Newsletter

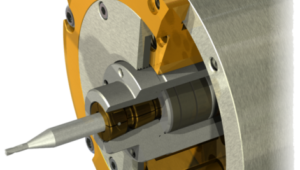

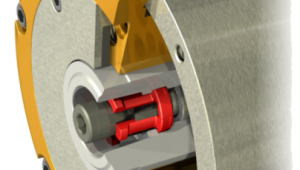

As the world’s first aerostatic tool spindle with HSK-E25 tooling system Levicron just don’t offer an ultra-precision bearing system combined with HSK tooling. Because it was designed to meet both, ultra-precision and CMC-functionality and robustness, no other aerostatic spindle on the market can meet with its speed and load capacity as well as thermal and dynamic stability. Where the Ultra-Precision Machining Industry now get an opportunity to add automated tool change to their machines the CNC Machine Tool Industry now get the chance to machine optical components without sacrifying productivity or automation. But beside the obvious advantages the customer gets even more on top. With a wear-free bearing system and an industry-leading thermal and dynamic stability machining complex parts over hours, days or week at even top speed doesn’t change the spindle properties at all. For the machine-user this means: Maintenance-free and stable operation, no matter how long the machining time.

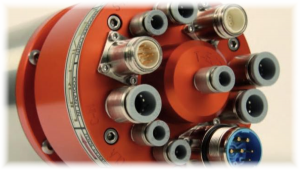

In this newsletter the reader can find the properties of our ASD-H25 and what it could mean to his applications. We also introduce our ASD-H25A with axial spindle connector that was specifically designed for closed Z-stocks.

Get the newsletter-PDF for more information.

Newsletter Content:

- ASD-H25 / ASD-Cx – Obvious benefits from using ultra-precision aerostatic solutions

- ASD-H25 – World’s first oppotunity for CNC Machines of machining ultra-precision parts

- ASD-H25 – World’s first opportunity to add an automated tool change to Ultra-Precision Machining and to increase productivity

- ASD-H25A – Our ASD-H25 with axial spindle connectors

ADDITIONAL INFORMATION

Subscribe to our newsletter …

DETAILS

| What: | Levicron Newsletter |

|---|---|

| When: | January 2013 |

| Where: | -,- |

Leave a Reply

You must be logged in to post a comment.