Paper // “Aerostatische Spindeln in der CNC-Fertigung”

- March 22, 2015

- Posted by: Levicron

- Category: Applications, News and Updates, Papers

ABSTRACT

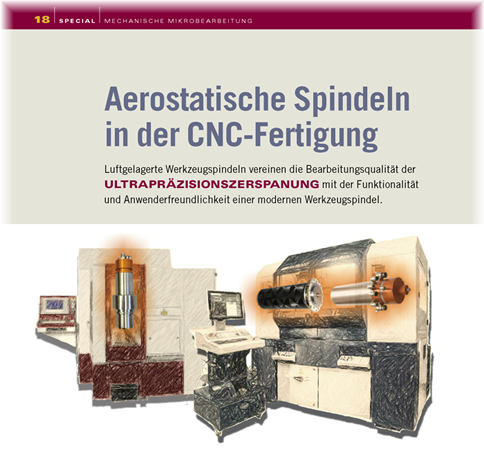

The great success of Levicron’s aerostatic tool spindles ASD-H25 and ASD-H25A confirm the initial thoughts of bridging the gap between Ultra-Precision and CNC Machining. With ultra-precision qualities, high speeds and CNC functionality like an automated HSK-E25 tooling system they give both machine types opportunities for new applications and markets.

Ultra-Precision Machining lacks of automation and productivity, and machining results often rely on the skills of the machine operator. CNC Machining on the other hand is characterized by a high level automation, but relies on conventional spindle solutions not capable of machining ultra-precision parts.

With Levicron’s ASD-H25 and ASD-H25A both markets get what they lack of. Ultra-Precision Machining now can make use of the automated HSK-E25 tooling system to adapt tool loaders and automated tool setting to increase productivity and machine safety. CNC Machining on the other hand now can machine optical components and high-precision parts without sacrifying CNC functionality. But to the obvious advantages of using aerostatic spindles Levicron can offer much more. Their ASD-H25 and ASD-H25A offers higher speeds at even much higher load capacities compared to other aerostatic spindle solutions and offer a thermal and dynamic stability no other solution can compete with. Especially for long machining times these spindles don’t change their properties, even when used for machining at top speed for days or weeks.

Journal Mikroproduktion covers all these aspects and gives an comprehensive overview of current applications and results with Levicron tool spindles.

INHALTE

- Properties of aerostatic bearings and their obvious advantages against conventional bearings

- Aerostatic spindle solutions for CNC Machining and Ultra-Precision Machining

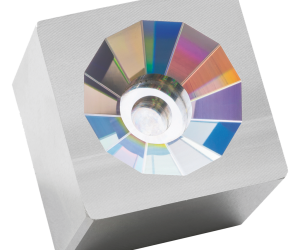

- Ultra-precision spindle solutions and tooling from Levicron

- CNC Machining solution from company Roeders, Germany, using aerostatic spindle solutions

- CNC Machining application: Coining Dies

- CNC Machining application: Dies for optical components

- CNC Machining application: Watch components

ADDITIONAL INFORMATION

Contact Details “Journal Mikroproduktion”:

http://www.mikroproduktion.com/footer-menu/impressum.html

Contact Details Company “Röders GmbH”, Germany:

http://www.roeders.de/maschinen/impressum/

DETAILS

| Publisher: | MIKROvent GmbH |

|---|---|

| Journal / Issue: | Mikroproduktion / 08-2015 |

| Author: | Dr. Ralf Dupont |

| Date: | 22. März 2015 |

Leave a Reply

You must be logged in to post a comment.